Corporation Social Responsibility

Fulfill carbon reduction, build green homes, emphasize environmental education

Internal control practice

In order to ensure the implementation of corporate governance and strengthen internal control and audit operations, Sesoda has set up an independent audit office under the board of directors. The audit office schedules an annual audit plan every year. After the board of directors passes it, it actively reviews the operating procedures of each plant and increases the control of the operating system and to prevent violations of the Code of Conduct in the implementation of internal audits. In addition to the annual audit plan, the audit office conducts on-site audits or document reviews based on risk, as well as irregular and special purposes. Project audits at various factories and regular audits of management systems such as ISO.

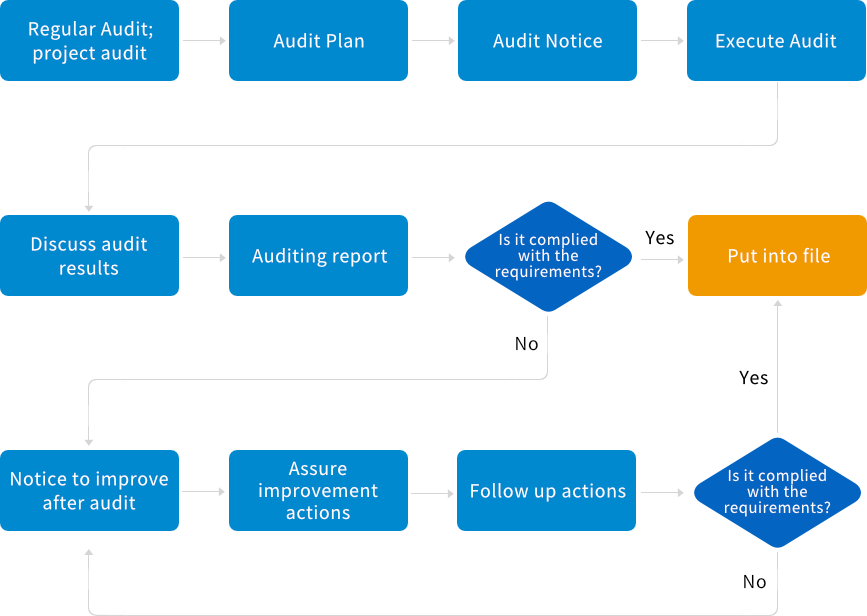

Audition Process

The Audit Office assists each department in self-inspection of the internal control system, senior supervisors' inspection and diagnosis operations every year. The Audit Office also provides timely improvement suggestions to assist the board of directors and managers in checking and reviewing the deficiencies of the internal control system, as well as measuring the effectiveness and efficiency of operations, as to be reasonable ensure the continuous and effective implementation of operational effects, compliance with laws and regulations, and financial reporting, and serve as a basis for review and revision of the internal control system. In addition, the audit supervisor will attend the board of directors to conduct audit business reports. The monthly internal audit reports and quarterly audit follow-up reports are submitted to independent directors for review. If a major violation or the company is in danger of major damage, the audit office is required Make a report immediately and notify the independent directors. A total of 196 audit projects were implemented in 2019, and the audit compliance rate reached 100%.

Risk Management

| Risk Project | Risk Description | How Sesoda takes |

|---|---|---|

| Financial risk |

|

Current implementation measures: Future goals

|

| Market competition risk |

|

Current implementation measures

Future goals |

| Operational risk |

|

Current implementation measures

Future goals |

| Environmental pollution risk | Polluting the environment and being punished by the competent authority. |

Current implementation measures

Future goals |

| Risk of interruption of raw material supply |

|

Current implementation measures

Future goal |

| Air and traffic risks in the communities around the factory |

|

|

| Climate change risk | Due to the impact of the greenhouse effect, climates around the world have fluctuated, with droughts, high temperatures, and heavy rains in various regions, resulting in desertification, depletion of arable land, and lack of water resources. |

|

| Compliance risk | The company has an illegal record, causing direct financial losses, loss of investor confidence, and damage to the company's goodwill. |

|

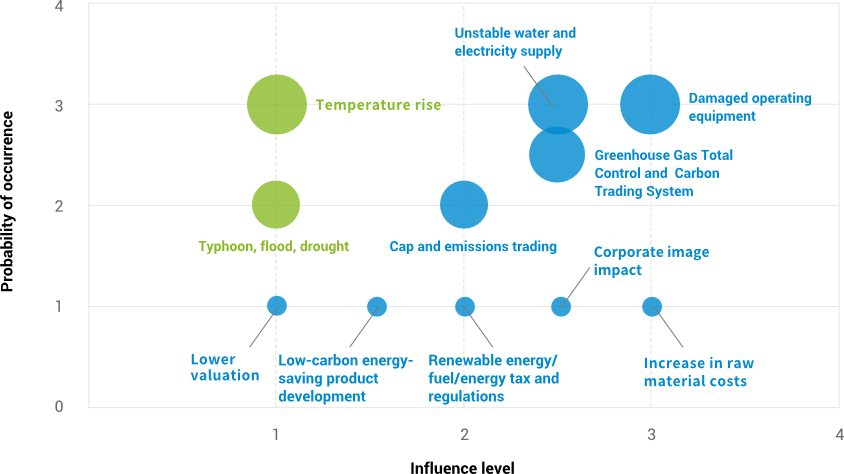

Climate change risks and opportunities

The impact of climate change on business operations and the disclosure of information on specific climate changes. In addition to regular reports to the board of directors and the financial risk management committee, Sesoda will let the board and senior management understand the impact of climate change on the company, and expose climate-related issues information, to provide investors and other stakeholders with consistent needs and to work with suppliers and partners to promote environmental sustainability; including the direct or indirect physical impact caused by extreme weather, the transformation impact of regulations, technology or market demand, and the matrix analysis of risks and opportunities caused by the company's operating activities due to other cultural and social aspects. Based on the analysis results, a risk management strategy plan is established as the core of climate change actions to estimate management costs and financial impacts. Through the above-mentioned collected data, the company's climate change governance is strengthened, and financial connections are systematically evaluated to reduce risks and grasp business opportunities. The company assesses the risks that climate change may face to the company in accordance with the "Risk Management Measures" every year, including (1) the impact of typhoon frequency and intensity on the transportation of raw materials, (2) changes in fertilizer demand, and (3) reduction in greenhouse gas emissions, etc. . Identify risk sources, risk analysis, risk assessment and risk treatment, and continue to improve and reduce the impact on the company.

The Risk Matrix of Climate Change

| Identification of the risk of climate change | Impact on company operations | Management measures to identify the risks of climate change |

|---|---|---|

| Operational equipment damage | Operation is interrupted due to climate disasters, such as the destruction of information mainframes or production equipment, resulting in production interruptions. | For information systems, strengthen the emergency power supply and backup mechanism. For physical branches, every time a strong typhoon or heavy rain warning is issued, take precautionary measures. |

| Unstable water and electricity supply | Production has been hit and operating costs have increased. | Improve water resource efficiency and use emerging water sources. |

| Increase in raw material costs | Due to climate change, the cost of raw materials for bulk commodities has increased, which will affect operations. | Based on the control of raw materials related industry sources. |

| Cap and emissions trading | The general temperature rise caused by climate change affects the production and operation costs of factories. | When performing company-wide maintenance, we will also review the replacement requirements and plan ahead of time to replace old equipment to deal with equipment with high carbon emissions and performance degradation. |

| Greenhouse Gas Total Control and Carbon Trading System | Capacity expansion is limited and operating costs increase. | Participate in carbon trading market and participate in renewable energy projects |

| Renewable energy/fuel/energy tax and regulations | Changes in regulations may affect green energy industry subsidies, and green energy industry development may be considered. | Seek competitive equipment manufacturers, research and development direction. |

| Corporate image impact | Failure to meet the expectations of stakeholders, causing damage to the company's reputation or image | Enhance investors' long-term investment willingness |

| Typhoon, flood, drought | Production is affected, leading to financial losses and lower revenue | Improve natural disaster resistance |

| Lower valuation | The credit collateral suffered damage due to climate change disasters. At present, most of the collateral are real estate, the credit ratio is low, and the impact strength is low. | A re-evaluation review of collateral is conducted every six months, and changes in real estate market conditions in various regions will be tracked regularly. |

| Low-carbon energy-saving product development | Product development costs increase. | Develop or expand energy-saving products and services. Meet customer demand for energy-saving products. Invest in energy-saving product development to increase revenue. |

| Temperature rise | Increase in electricity consumption, rising costs and carbon emissions | Promote low-carbon green production equipment Save electricity, save costs |

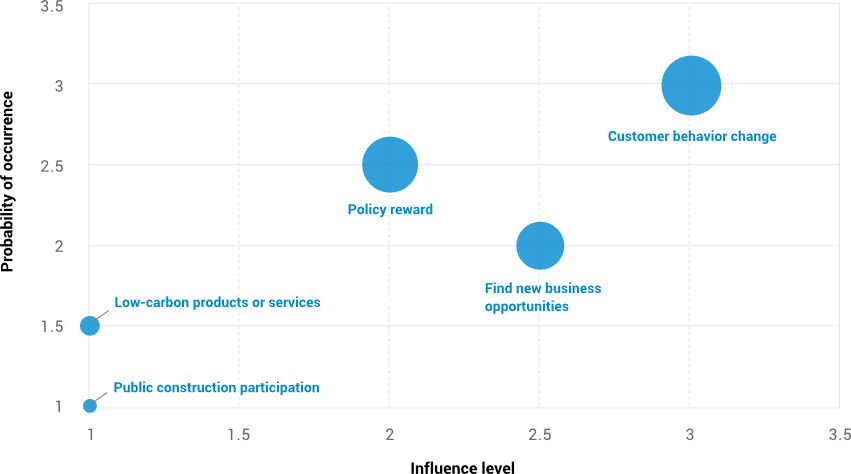

The Opportunity Matrix of Climate Change

| Climate change risk identification | Identification of climate change opportunities | Possible business development for company operations |

|---|---|---|

| Policy reward | When replacing equipment, apply for relevant energy-saving subsidies in accordance with government subsidy policies. | When purchasing additional production equipment, cooperate with the purchase of equipment that meets the requirements, and submit the subsidy application to the government window after collecting relevant information. |

| Customer behavior change | Climate change and weather conditions have a huge impact on agricultural farming, and mutually affect customers' desire to buy and enthusiasm. | In response to market demand, integrate resources, timely and effectively adjust production capacity, supply to meet market needs, and enhance development potential. |

| Low-carbon products or services | Following the development of domestic and global low-carbon and green energy trends. | In the future, the proportion of investment-friendly products will be increased. |

| Find new business opportunities | Assist in the expansion of green energy cases in other countries, which is conducive to medium and long-term business growth. | With large-scale energy projects such as co-generation equipment, the domestic industrial chain continues to improve, and the investment possibilities of related projects in the future are evaluated. |

| Public construction participation | Respond to the government's green energy policy | In recent years, we have actively participated in energy-saving programs and continued to enhance the image of green energy. |

Compliance

Formulate policies, commitments, and future goals:

The management level expresses the importance of this issue by formulating relevant norms, conducting education and training and advocacy, regular assessment and compliance with declarations, etc. to express the importance of this issue. It also extends to external stakeholders and provides adequate reporting channels and protections to demonstrate this The company's ethics and compliance culture.

Investment resources:

In terms of environmental protection, the county government has proposed changes and applications for the discrepancies in the establishment permits and operating permits. Zhong Ding Engineering Co., Ltd. has been appointed to actively conduct environmental protection assessment and improvement operations, and strive to reduce Air pollution discharge; in terms of occupational safety and health, we strengthen employee's awareness of workplace safety through training courses and establish a plan for human factors engineering and illegal infringement prevention.

Grievance mechanism:

The company has a whistle blower system to provide employees and external personnel with an effective and appropriate grievance mechanism. Appropriate responses will be given to the concise, convenient and unobstructed channels for complaints that endanger labor rights. Sesoda deeply recognizes that only good laws and regulations follow the practice to match the company's internal control system, and through on-site visits to colleagues' education, training and audits, it confirms that colleagues' business execution is in compliance with laws and regulations and the company's internal regulations, thereby reducing the company's risk of violations , to avoid direct economic losses of the company, damage to shareholders' rights and damage to corporate image.

To this end, the company has invested resources in compliance with laws and regulations. First, we formulate relevant policies. The management uses relevant regulations to carry out education, training and promotion, regular evaluations, and compliance declarations to express the importance of this issue, and it also extends to external interests. Related parties, provide their whistle blowing channels and whistle blower protection instructions, and then reflect Sesoda's corporate culture of ethics, integrity and legal compliance.

On the issue of local environmental protection in the plant area, the Yilan County Government ordered the suspension of work in 108. The Yilan County Government approved the trial operation on January 14, 2019; the Appeal Review Committee of the Environmental Protection Department of the Executive Yuan was resolved in February 2019 The suspension order of the original Yilan County Government was revoked, and the main plant is now operating normally.

In the future, Sesoda will strictly require every colleague to abide by the company's internal rules and regulations. Any violation of the company's internal rules will be regarded as improper behavior. In addition to punishing them in accordance with relevant company regulations, they will also be dealt with in accordance with the law. The company will review and improve immediately after the occurrence of an abnormality, strengthen personnel education and training, enhance the ability of independent inspection, prevent and strengthen management from the source, and hope to prevent the occurrence of similar abnormalities, and continue to move towards the goal of zero violations of environmental protection and adhere to strict self-discipline. To ensure that no illegal records will occur in the future, and to protect the rights and interests of internal and external stakeholders.

Occupational safety and health violation statistics:

In 2019, Sesoda received no complaints related to labor human rights, and the official website did not receive any complaints against the company from external stakeholders.

Sesoda 2018~2019 Statistics of environmental violations in the year

| Year Project | 2018 | 2019 | ||

|---|---|---|---|---|

| Case | Fines (10,000) | Case | Fines (10,000) | |

| Air Pollution | 6 | 620 | 0 | 0 |

| Water Pollution | 1 | 6 | 0 | 0 |

| Waste Pollution | 2 | 1.2 | 1 | 5.4 |

| Health/Safety | 4 | 12 | 2 | 30 |

| Total | 13 | 639.2 | 3 | 35.4 |